SC/APCPre-Connectorized Optical Fiber Drop Cable Test method 1 Terms and definitions

1.1

Name:Pre-Connectorized Optical Fiber Drop Cable

1.2 Requirement of Pre-Connectorized Optical Fiber Drop Cable

1.3 Structure Requirements

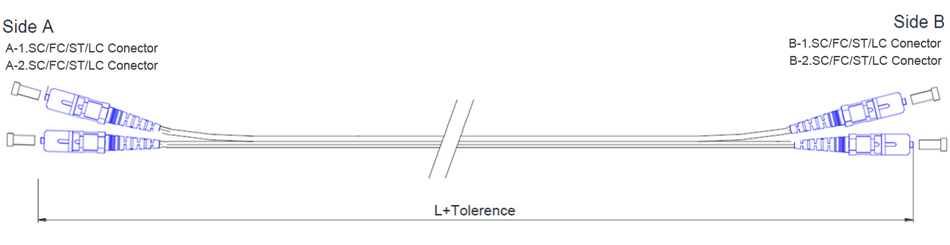

Pre-Connectorized Optical Fiber Drop Cable is composed of butterfly type introduction cable and fiber optic removable connector plug.

According to the structure classification, it can be divided into: single-end prefabricated end type and double-end prefabricated end type. The schematic diagram of the structure is shown in Figure 1 and Figure 2.

1.4 Requirements for optical Fiber Connector Plugs

1.4.1 Requirements on the Size of the Optical Fiber connector

The length of the Pre-Connectorized Optical Fiber Drop Cable plug (including the protection sleeve) should not be greater than 60mm, which is shown in Figure 3.

Interface graphics and matching size should meet the requirements IEC 61754,YD/T 1272.3-2005

1.4.2 Requirements for the End face of the Connector

The end faces of optical fiber connectors are classified into the following 2 types

a) UPC type :A pin body with a spherical polishing surface and achieving physical contact (UPC) is provided

b) APC type :A pin body with an 8 degree oblique spherical polishing surface (APC8°) and physical

contact is achieved The end face of the insert body should meet the requirements of IEC 61754,YD/T 2152-2010。

1.4.3 Structural Requirements for the Connector of the Optical Fiber

| 1:Ferrule | 2.inner body | 3.outer body | 4.Spring | 5.Set head block |

| 6.Metal tail handle | 7.crimp contact | 8.The tail sheath | 9.FTTH cable | |

The connection between the optical fiber connector plug and the ftth cable should be firm and reliable. The connection relay of the riveting pressure connector shouldact on the sheath and strengthening members of the ftth cable, should not deal with the optical fiber core in the ftth cable to impose long-term stress.

The optical fiber connector used for optical cable connection should be fixed at the end of the cable.

This fixation can not affect the normal axial range of movement of the pin body, but also bear a certain tension.

When the tail cable is subjected to a normal pulling force of no less than 9.8N, the pin body cannot be pulled back to ensure the normal operation of the connector.

1.5 FTTH cable requirements

FTTH cable introduction shall meet the requirements of Q/CT 2348.

The optical fiber should be a single-mode optical fiber conforming to ITU-T G.657A standard

1.6 The length of Pre-Connectorized Optical Fiber Drop Cable

Pre-Connectorized Optical Fiber Drop Cable should be able to be delivered in accordance with the requirements of the customized length, it is recommended to customize according to the step length of 5m or 10m , such as: 20 m, 25 m, 30 m, 35 m, 50m 70m 100m etc

1.7 Environment Requirements

a) Operating temperature:-40℃~+70℃。

b) Storage temperature:-40℃~+70℃。

c) Relative humidity:≤95%(+30℃时) 。

d) Barometric pressure:62kPa~106kPa。

1.8 Material Requirements

The materials used should meet the following requirements:

a) The combustion performance of the plastic parts used for Pre-Connectorized Optical Fiber Drop

Cable SC plug should conform to the provisions of GB/T 5169.5-2008 <<Electrical and Electronic products fire hazard test – Part 5: Test flame needle flame test Method Device, Confirmation test method and guide>>, and the duration of the test flame is 10 seconds.

b) The sheath of FTTH Cable shall be made of flame retardant material, and its flame retardant performance shall meet the requirements of 6.4.4.3 in Q/CT 2348-2011 <<Technical Requirements for The Introduction of FTTH Cable by China Telecom Users (Interim)>>.

c) Two strengthening members shall be symmetrically placed on the FTTH cable, and the requirements of strengthening members shall meet the requirements of 6.1.4 in Q/CT 2348-2011.

d) Pre-Connectorized Optical Fiber Drop Cable can withstand the required test conditions, the adhesive used to make SC plug has no adverse effect on the plug structure, its physical, chemical and optical properties should match the butterfly introduction cable, must not damage the optical properties of the prefabricated end butterfly introduction cable.

e) Comply with RoHS standards, can not pollute the environment, in line with environmental protection standards.

f) When the finished product is damaged, its components are not allowed to cause harm to people

2 Performance requirement

2.1 Optical Performance Requirements

Table1Optical performance requirements

|

NO |

Test |

L≤20m |

20m<L≤50m |

50m<L≤100m |

100m<L≤200m |

|

a |

Insertion loss(1310nm)1 |

≤0.3dB |

≤0.34dB |

||

|

b |

Insertion loss(1550nm)2 |

≤0.3dB |

≤0.32dB |

||

|

c |

Return Loss(UPC)3 |

≥47dB |

≥46dB |

≥45dB |

≥44dB |

|

d |

Return Loss(APC)4 |

≥55dB |

≥51dB |

≥49dB |

≥46dB |

| 1More than 200m Insertion loss ( 1310nm):0.30dB + L×0.36dB/1000m2More than 200m Insertion loss ( 1550nm):0.30dB + L×0.22dB/1000m3More than 200m Return Loss ( UPC):≥40dB4More than 200m Return Loss (APC):≥40dB | |||||

2.2 Environmental Performance Requirements

The Pre-Connectorized Optical Fiber Drop Cable shall meet the environmental performance test requirements specified in Table 2 and the optical performance requirements specified in Table 1.

Table 2 Environmental Performance Requirements

|

NO |

Test |

Test condition |

Requirements |

|

|

Change ininsertion loss(dB) |

Shape change |

|||

|

a |

high temperature |

+70℃ 96h Test optical performance |

≤0.2 |

No mechanical damage, such as deformation, Cracking, relaxation and other phenomena |

|

b |

low temperature |

-40℃ 96hTest optical performance |

≤0.2 |

No mechanical damage, such as deformation,Cracking, relaxation and other phenomena |

|

c |

Temperature cycle |

( 40℃~70℃) 2121 times cycle, 168h |

≤0.2 |

No mechanical damage, such as deformation,Cracking, relaxation and other phenomena |

|

d |

Damp and hot |

+40℃ 95%, 96h Test optical performance |

≤0.2 |

No mechanical damage, such as deformation,Cracking, relaxation and other phenomena |

|

e |

In water |

Room temperature, water168h |

≤0.2 |

No deformation, foaming, roughness, Peeling and other phenomena |

| Note: 4.6~4.12 for specific test conditions and methods | ||||

2.3 Mechanical Performance Requirements

Comply Q/CT 2348-2011《Technical requirements for the introduction of butterfly optical cable by China Telecom users》.Table1

Table1 Mechanical requirements Test methods

|

NO |

Test |

Test condition |

Requirements | |

| Change ininsertion loss(dB) | Shape change and other standards after test | |||

|

a |

Vibration |

Frequency: 10-55Hz; Sweep frequency: sweep frequency once /min, frequency range 45Hz;Amplitude: 0.75mm single amplitude;Time: 2 hours in each direction; |

≤0.2 |

No mechanical damage, such as deformation, cracking, relaxation, etc |

|

b |

Drop |

Height: 1.5m from the sample head;Times: 8 times; |

≤0.2 |

No mechanical damage, such as deformation, cracking, relaxation, etc |

|

c |

Repeatability |

Insert and unplug: 10times |

≤0.2 |

No mechanical damage, such as deformation, cracking, relaxation, etc |

| d | Mechanicaldurability | Insert and unplug:500times | ≤0.2 | No mechanical damage, such as deformation, cracking, relaxation, etc |

| e | Tensile | Between plug and cable:Load:50, Test optical performance,10min; Load:60N,Test optical performance, 10min; | ≤0.2 | No mechanical damage, such as deformation, cracking, relaxation, etc |

| f | Torsion | load: 50N; Rate: 10times/min;times: 200; | ≤0.2 | No mechanical damage, such as deformation, cracking, relaxation, etc |

| g | Plug, pull force | Force measuring instrument; | —— | No mechanical damage, suchas deformation, cracking, relaxation, etc insertion force:≤19.6N ;withdrawal force:≤19.6N. |

| h | Tensile strength of locking mechanism | Load: 40N; Time: 10min; | ≤0.2 | No mechanical damage, such as deformation, cracking, relaxation, etc |

| i | Insert elastic fatigue resistance | Point H=6.9 mmPress the number of times500times; | ≤0.2 | No mechanical damage, the core can return to the original datum position |

2.4 Package and Transportation

Pre-Connectorized Optical Fiber Drop Cable Test method shall be equipped with dust caps. Each prefabricated end type butterfly introduction cable shall have independent packaging coil, coil diameter shall not be less than 25 times the diameter of the tail cable.

The package should be marked with product model, production batch, production date, manufacturer’s name and implementation standard number.

2.5 Storage

Pre-Connectorized Optical Fiber Drop Cable can not be placed in the open air or serious corrosion environment for a long time, should be stored within the storage temperature range.

Post time: Apr-03-2022